Fleet Brochures & Technical Information

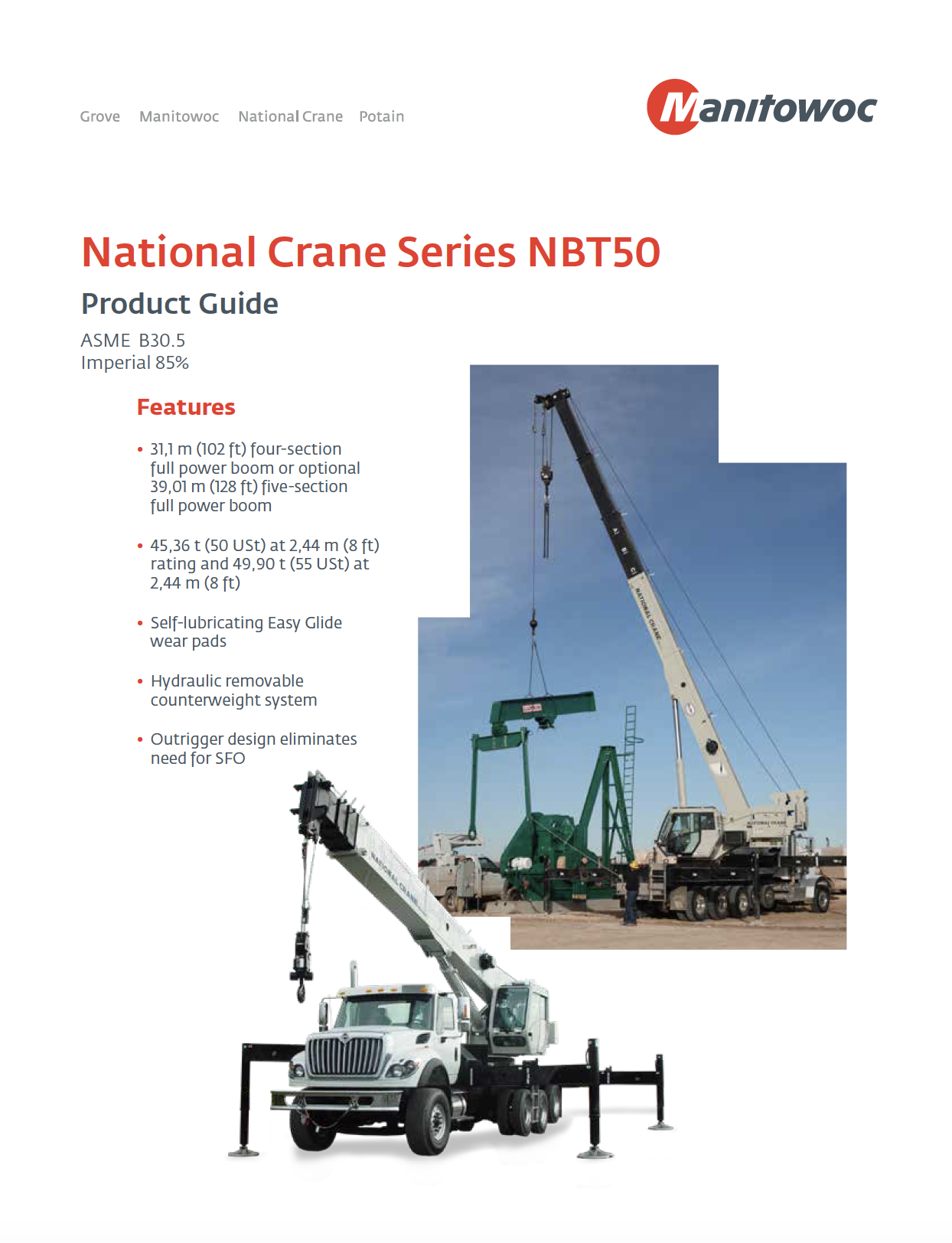

National NBT50

Best in class performance and serviceability

The Series NBT50 represents the pinnacle of machine performance, combining the latest in both hydraulic and electronic machine control. This product provides premium operator comfort with the latest Manitowoc cab design, simplified machine setup with no need for an SFO and front bumper control of the hoist(s).

Speedy-reeve boom tip and sheave blocks simplify rigging changes by decreasing the time needed to change line reeving

Easy Glide boom wear pads reduce the conditions that cause boom chatter and vibration.

Pressure compensated, load sensing hydraulic system

PTO mounted axial piston pump

Superstructure mounted reservoir with integral suction valve/filter, return filter, sight gauge

Oil cooler with 406 mm (16 in) fan and temperature sensor

Pressure transducers integral to the lift cylinder holding valve

LMI system features a 178 mm (7 in) graphical, color display.

Real-time crane information is displayed with numerous operator features

LMI system also displays key truck diagnostics such as fuel level, coolant temperature and DPF status.

Dual axis controls are optional for superior operator control.

Standard air conditioning, diesel heater and ergonomic seats

Manitex TC400

Versatile. Affordable. User friendly.

The TC400 series telescopic cranes are built to meet the wide-ranging needs of owner operators who may use it for residential construction one day and bridge work the next. No matter what the task, the 40-ton line of telescopic crane is designed to get you to the job and on the job quickly.

With it, you can:

Travel to and between job sites at highway speed on a commercial chassis

Set up quickly with radio outrigger controls

Operate comfortably and confidently in its tiltable cab

Link-Belt RTC 8050 II

Remarkable control, reliability and capacity performance

Powerful diesel engine and direct coupled transmission

Hydraulic disc brakes for both service brakes and parking brake

Weather proof electrical connectors and relays throughout for outstanding long-term reliability

Full lighting package includes cab lights, headlights, turn indication, marker, backup, and stop

Pre-painted components and plated hardware

Complete Link-Belt vision packageincluding right-sideswing, main and auxiliarywinch, and rear-view cameras

Link-Belt RTC 8065 II

Fully rigged transport of less than90,000 lbs |40 823 kg

Market leading capacity for its class

4-Link suspension with optionalHydro-gas ride system

Jobsite maneuverability

Folding front and rear ladders to prevent damage during loading and unloading for transport

Rugged, lightweight steel pontoons with storage locations for transport

Steering modes are chosen and performed with the steering wheel and include independent front, combination, “crab”, and independent rear steering.

Wide profile lug-type tires for excellent traction in muddy and sanding conditions

Link-Belt HTC 86100

Roomier and quieter operator’s cab

Extra large windows throughout for excellent visibility

Excellent ventilation via a large sliding door, side and rear windows, and hinged roof window

Single or dual axis, hydraulic operated controller mounted on armrestfor outstanding operator comfort

6-way adjustable power tilting seat

All gauges, switches, indicators, and controls are located in the operator’s forward line of sight

All gauges and switches are backlit forexcellent visibility in low light conditions

Winch and right side swing view cameras

In cab comfort is maintained by the standard heater and air conditioning

Link-Belt HTC 86110 - New crane!

Operator’s cab provides ergonomic comfort and control

Extra-large windows throughout for excellent visibility

Single or dual axis, electronic operated controller mounted on armrest for outstanding operator comfort

6-way adjustable power tilting seat

All gauges and switches are backlit for excellent visibility in low light conditions

All new lattice fly erection and stowing assist cylinder with new efficient jib pinning design for ease of assembly/ disassembly

Comfort Carrier Cab:

Dash-mounted comprehensive instrumentation with back-lit gauge

Fully adjustable air-ride fabric seat

Suspended pedals

Cruise Control

The only greaseless, high-capacity formed booms designed and built in North America!

Road and job site ready!

Automated transmission (no clutch pedal) −12 speeds forward, 2 speeds reverse with two modes of operation: fully automatic and semi-automatic

Job site travel is permissible with counterweight for exceptional job site versatility.

Work light package — Standard with illuminated compartments and controls for night-time operation including illuminated storage

Four illuminated locking storage boxes

Tadano ATF-100G-4

Telescopic boom

6 sections, made of high tensile, fine-grained steel, consisting of 1 base section and 5 telescopingsections extended by means of a single telescopic cylinder.

All telescope sections extendable under partial load. 36.4 ft(11.1 m) to 168.0 ft (51.2 m) long. Boom head with 7 sheaves.

Axles

1st axle: steered, not driven.

2nd axle: steered, driven.

3rd axle: steered, driven, with transverse and longitudinal differential lock.

4th axle: steered, driven, with transverse differential lock.

Carrier cab

Two-man full width cab of composite (steel sheet metal and fibre-glass) structure, with safety glass,air-cushioned adjustable seats (driver seat with heater) and engine dependent water heater, air conditioning, radio/ CD-player, complete controls and instrumentation for roadtravel. Cruise control with hill breaking feature functions.

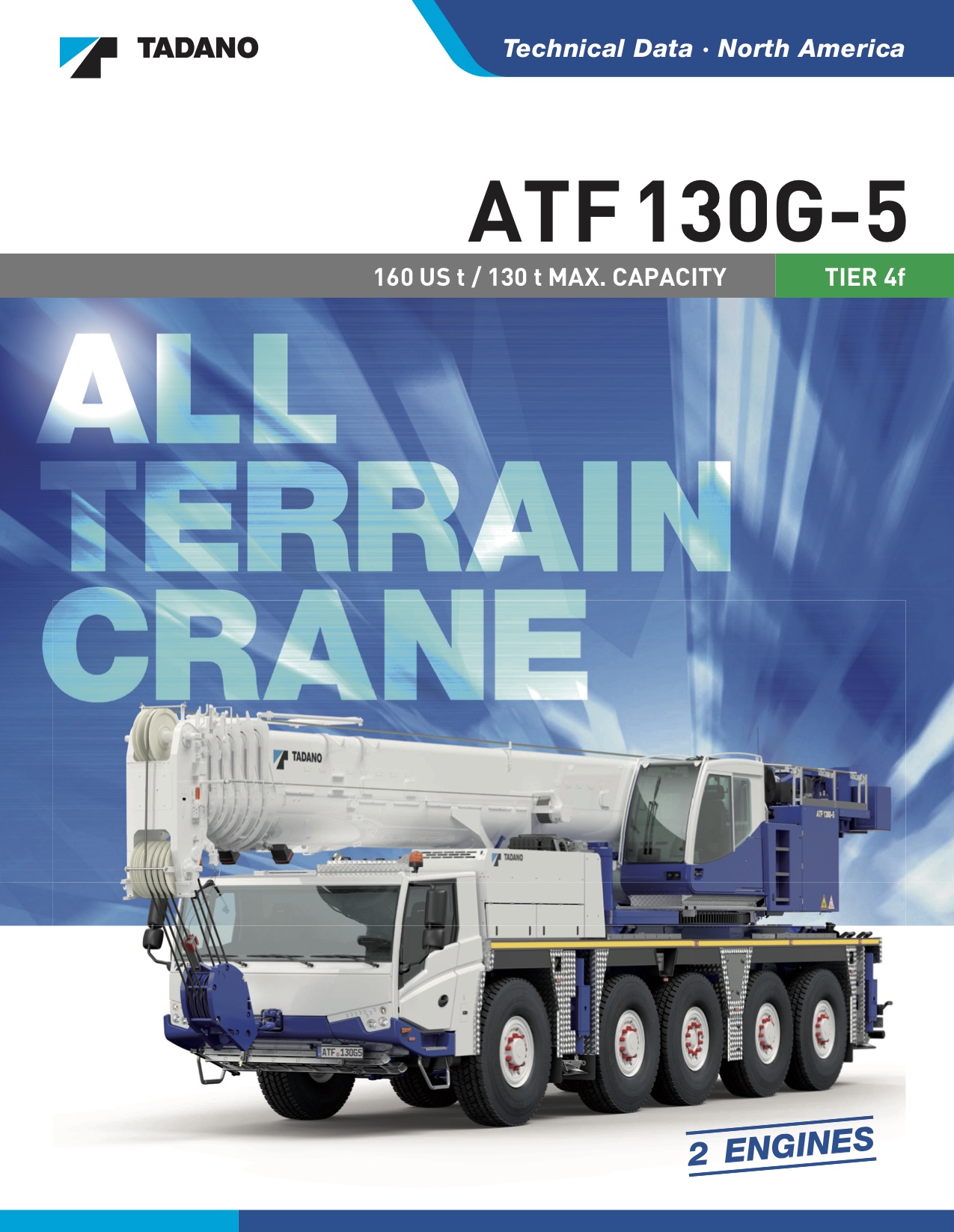

Tadano atf 130G-5 All Terrain Crane

Standard

Tilting inner-cockpit

Two-engine configuration

Two-stage transfer case

ZF-Servocom, dual circuit hydraulic steering

5 outrigger positions

Independent programmable engine pre-heaters

Optional

Hoist camera

Tire pressure monitor system

Additional hydraulic oil coolers

Hook block storage for 3-sheave block

Anti-fall protection on boom

Design Enhancements

Multi-function display with full diagnostic system

New bi-fold jib design with hydraulic deployment

Flat front lower windscreen

Integrated heavy lift jib

Multiple counterweight charts

Link-Belt ATC 3210 — Newest Addition to our fleet

Best All-terrain crane on the market

Outstanding mobility on the road and on the job site

Unlike any all-terrain, the ATC-3210 can travel at a highway speed of 62 mph | 100kph

Tier 4f off-highway emission compliant engine

2013 EPA on-highway emission-compliant engine

Next generation tilting operator’s cab up to 20°

Pin & latch boom with attachment flexibility

Job site travel is permissible with all 115,500 lbs. | 52.4t of counterweight for exceptional job site versatility

Liebherr LTM 1200-5.1

The LTM 1200-5.1 has a very long telescopic boom which can be extended using various lattice extensions and a folding jib. Its entire operating range features outstanding load capacities. Sales and Service- Our customers can rely on a worldwide sales and service network. Liebherr stands for outstanding safety standards and top performance. We invest heavily in research and development to ensure this. The main focus of this work is to ensure customer benefits.

A long telescopic boom, high capacities, an extraordinary mobility as well as a comprehensive comfort and safety configuration distinguish the mobile crane 1200-5.1 from Liebherr. The 200-tonne crane offers state of the art technology for more convenience in practical operation.

72 m long telescopic boom and 7 m telescopic boom extension

12.2 m – 36 m long folding fly jib, hydraulically adjustable (option)

Capacity 10.6 t at the 72 m long telescopic boom

Great flexibility of use due to optimum lifting capacities with full and partial ballast

Active, speed-depending rear-axle steering

Pneumatic disc brakes

LICCON2-control with mobile control and display unit BTT

Liebherr LTM1250-6.1

Carrier

LIEBHERR 6-axle carrier with hydro-pneumatic NIVEAUMATIC-SUSPENSION with level adjustment. LIEBHERR diesel engine with 450 kW (612 HP) exhaust emission ace. to 97/68/EC and EPA/CARS. ZF TC-Tronic transmission with torque converter and retarder. Transfer gearbox. Drive 12 x 6. Tyres 525/80 R 25 (20.5 R 25), ZF-steering system - 2 circuits, axles 1, 2, 3, 5 and 6 steered, crab walk. Compressedairservobrakesystem- 2 circuits. Axles, driveshaftsandsuspensioncylinders demandinglow maintenance. Spacious, corrosion resistant carrier cabin with engine-independent heating incl. timer and CO-radio. Hydraulic outriggers with rigidly mounted outrigger pads. Electronic inclinometer, electronic supporting pressure indication, automatic support levelling. Illumination of supporting area. Acoustic reverse drive alarm. Manoeuvring coupling at front and rear. Standard acceptance tests of carrier.

Superstructure

LIEBHERR roller-bearing slewing ring connecting carrier and superstructure. Central greasing. LIEBHERR diesel engine with 180 kW (245 HP), exhaust emission ace. to 97/68/EC and EPA/CARB. Hydraulic system with 2 axial-piston swivel pumps with electronic capacity control for luffing and telescoping gear with open oil circuits, one axial-piston swivel pump each for slewing and hoisting gear with closed oil circuit. Electro-hydraulic control of crane. Oil cooler. Telescopic boom consisting of the pivot section and 5 telescope sections, boom length 236', TELEMATIK. Galvanised and powder-coated superstructure cabin with engine-independent heating incl. timerand CO-radio. Tiltable hydraulically backwards by20°. Counterweight 159,500 lbs, automatic ballasting from superstructure cabin. Safety devices including LICCON overload safety indicator with electronic inclinometer (incl. standard program). TEST SYSTEM for servicing. LICCON-Lift Planner. Wind gauge. Flight warning light. Standard acceptance tests of crane.